“WE NEED YOUR SUPPORT!!! 2021 SME MFG EXPO”

WE did it! Since 2015, the SME and SVMA have been working with several regional partners to bring a Manufacturing focused Expo to Sacramento and we made it happen ). We are now asking EVERYONE in our circle of influence to show support for this event by signing up as attendee or exhibitor. Please RSVP now. The first 500 people will be entered into a raffle to win $CASH$ prizes and a FRANK STALLONE GUITAR on the day of the event.

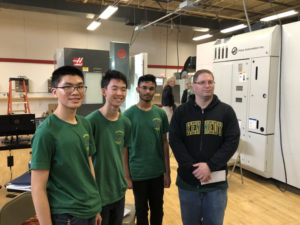

Challenged by competitors with many more years of experience, the JFK MaD students were able to perform under pressure and complete complicated tasks in a limited amount of time. This event showcased a culmination of advanced skills obtained, as students in the Manufacturing and Design Pathway. These students validated many years of rigorous curriculum development and proven learning outcomes. Congratulations to JFK MaD Lead Instructor Mr. Rob Greene and the students, Franklin Huang, Kushal Nand and Jason Liu for all their hard work and dedication. These students were awarded scholarship funds, free Kennametal tooling and a cash prize to the program at Kennedy High School.

Challenged by competitors with many more years of experience, the JFK MaD students were able to perform under pressure and complete complicated tasks in a limited amount of time. This event showcased a culmination of advanced skills obtained, as students in the Manufacturing and Design Pathway. These students validated many years of rigorous curriculum development and proven learning outcomes. Congratulations to JFK MaD Lead Instructor Mr. Rob Greene and the students, Franklin Huang, Kushal Nand and Jason Liu for all their hard work and dedication. These students were awarded scholarship funds, free Kennametal tooling and a cash prize to the program at Kennedy High School.